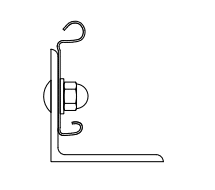

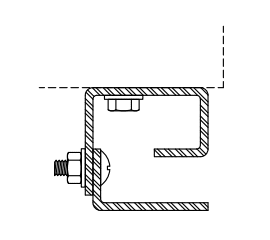

Steel pipe houses torsion spring assembly and supports curtain with a maximum deflection of .03 inch per foot of width. Torsion springs are mounted on a continuous cold rolled steel shaft, adjustable by a tension wheel outside one bracket.

Square hood formed from 24 gauge (galvanized steel) (stainless steel) sheet, reinforced with tip and bottom flanges to limit deflection.

Slide Bolt locks standard for push-up operation, optional otherwise.

Grifco Fire Door Chain Hoist and Liftmaster FDCL Fire Door Motor, provide smooth automatic closing without tension loss, saving time and money on testing and resetting.

Smoke Detectors: Photoelectric (detects smoke and heat) require connection to a release device (XPBB) or FDC Operator.

Brush seals factory applied to guides and footpiece, field installed on header,

to aid in smoke and draft control.

Key or thumbturn cylinder lock installed on footpiece for added security and

convenience.

Available on all exposed surfaces.

Hot dip Galvanizing available on footpiece, guides and brackets.

Finish:

Galvanized steel slats and hoods are pre-finished with a baked on gray

polyester primer before forming (Tan or bare available upon request). Steel

footpiece, guides and brackets receive one coat of rust inhibiting color

matching primer. Exposed stainless steel provided with #4 finish.

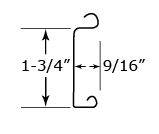

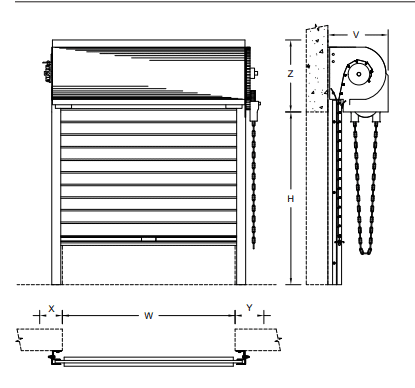

LFP – Push-Up

LFA – Awning Crank

LFC – Chain

LFM – Motor

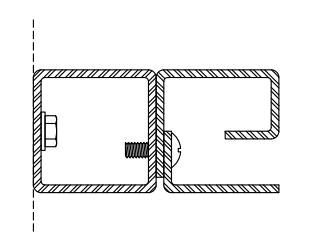

(For Between-Jamb Mount,

change letter ‘F’ to ‘J’)

Rocket Garage Doors Copyright 2024 © All Right Reserved